MLTL-4 Mass Loaded Transmission Line Speaker Build Manual

This is a mass loaded transmission line speaker, that uses a 4” paper cone woofer, and a 3/4” soft dome tweeter. It is a slim stand mount speaker, and the cabinet is tuned to 30Hz. Both drivers are from Dayton Audio, and they have excellent performance.

Mass loaded transmission line speakers have the best bass quality of any speaker I have heard in my nearly 4 decades of music listening. They also have wonderful “unboxy” midrange, and have a spacious soundstage; if it is there in the recording. The midrange of transmission line speakers is also much more open than conventional designs; and may rival open baffle designs.

The cabinet is 6”W x 19”H x 14”D / 151mm x 483mm x 313mm and is made with 18mm thick material - either Baltic birch or MDF. Each finished speaker built with the Baltic birch flat pack weigh a bit less than 20.4 lbs / 9.3 kg. The corner joints of are designed to have a 12mm x 12mm chamfer; but they can be left square, if you choose. I can provide CAD files to make CNC cut files - the build manual includes drawings of straight cut panels, and the CNC version of the panels. It can be built with a table saw and plunge router, and/or with a CNC machine.

A strong benefit of a “folded” transmission line design is the internal baffles not only form the specific volumes and dimensions required for the correct tuning for the woofer - they also form asymmetrical bracing for the cabinet. Less obvious is the fact that the internal air pressure in a TL design is lower than an equivalent sealed, or even a ported design. This greatly reduces the panel resonances - and this is possibly why the midrange and bass are more open and clearer. The woofer has less of an “air spring” behind it, so it is more closely reproducing the music in the recording.

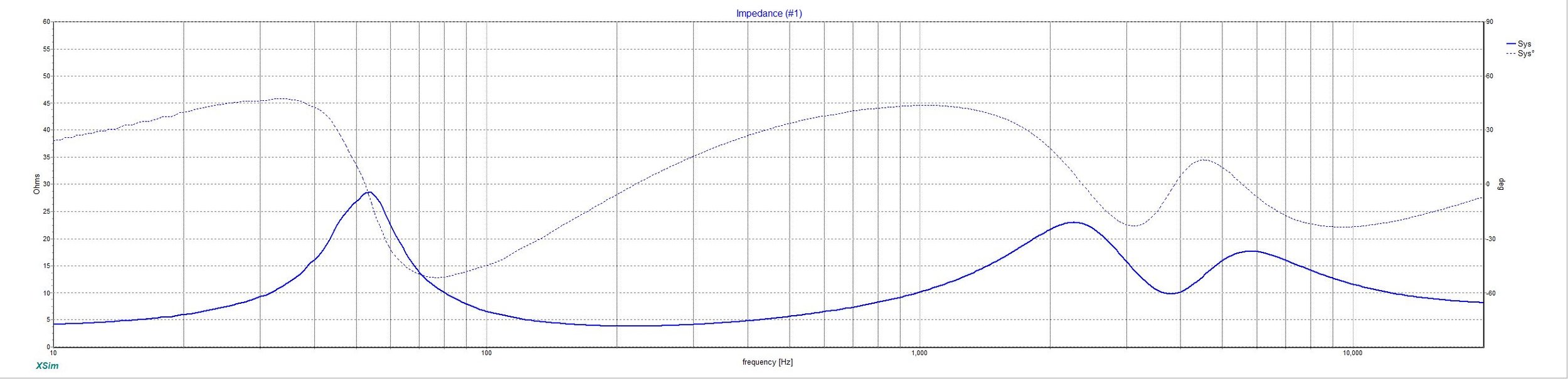

I have also spent a lot of time designing and refining crossover designs. It is a 3rd order series crossover design. A series crossover diverts the signal that is filtered out for one driver, and diverts it to the other driver. And so a series crossover can be slightly more efficient, and they tend to have a smoother more even impedance; which can make them better for use with tube amplifiers.

A transmission line speaker cabinet is a tuned “column” of air behind the driver - it has lower distortion and greater bass extension that conventional sealed or ported designs. I used a program called Hornresp (short for Horn Response), and carefully matched the computer acoustic model to the cabinet design, using DataCAD.

The total cost of the pair of woofers and a pair of the dome tweeters is about $50 - both are Dayton Audio units from Parts Express. The crossover uses all air core inductor coils, with larger gauge coils for a lower DCR. This is important for the best possible bass quality. We highly recommend bypass capacitors, that open up the soundstage with clear layered and extended treble. The benefits of high quality crossover components cannot be overstated. The build manual includes clickable links for 3 options - “good, better, best” lists of crossover parts quality.

These speakers are average sensitive - the woofer is rated at 86.8dB @2.83V @1 meter. But the crossover lowers this somewhat, and the transmission line may increase it somewhat. I listen at a lower volume setting on my preamp than the other speakers I own. The MLTL-4 speakers are 4-6 ohm nominal impedance - and has a minimum of about 4.0 ohms. I am using the amazing AkitikA GT-104 amp - it is rated at 60W/ch @ 4 ohms and ~35W/ch @ 8 ohms - it barely gets warm even after long listening sessions. Any amp that is rated for ~4 ohm speakers will probably work very well, with the MLTL-4 speakers.

The manual includes drawings in inches and in millimeters, and includes a stand that integrates with the chamfered cabinets. Also included are CNC version of the panels. I can provide the CAD files for these, if you want to build it this way.

We are very happy to announce that you are now able to order assembled crossovers for the MLTL-4! E-Zee’s Crossovers has “good/better/best” parts lists that are similar to our build manual - all air core inductor coils, metalized film capacitors, and very low/non-inductive resistors. If you want to build one of our MLTL-4 speakers - but building the crossover was holding you back - then you have this option. Visit their website, and email them for pricing. E-Zee’s Crossovers <elon@ezeescrossovers.com>

MLTL-4 Mass Loaded Transmission Line Speaker Build Manual

This is a mass loaded transmission line speaker, that uses a 4” paper cone woofer, and a 3/4” soft dome tweeter. It is a slim stand mount speaker, and the cabinet is tuned to 30Hz. Both drivers are from Dayton Audio, and they have excellent performance.

Mass loaded transmission line speakers have the best bass quality of any speaker I have heard in my nearly 4 decades of music listening. They also have wonderful “unboxy” midrange, and have a spacious soundstage; if it is there in the recording. The midrange of transmission line speakers is also much more open than conventional designs; and may rival open baffle designs.

The cabinet is 6”W x 19”H x 14”D / 151mm x 483mm x 313mm and is made with 18mm thick material - either Baltic birch or MDF. Each finished speaker built with the Baltic birch flat pack weigh a bit less than 20.4 lbs / 9.3 kg. The corner joints of are designed to have a 12mm x 12mm chamfer; but they can be left square, if you choose. I can provide CAD files to make CNC cut files - the build manual includes drawings of straight cut panels, and the CNC version of the panels. It can be built with a table saw and plunge router, and/or with a CNC machine.

A strong benefit of a “folded” transmission line design is the internal baffles not only form the specific volumes and dimensions required for the correct tuning for the woofer - they also form asymmetrical bracing for the cabinet. Less obvious is the fact that the internal air pressure in a TL design is lower than an equivalent sealed, or even a ported design. This greatly reduces the panel resonances - and this is possibly why the midrange and bass are more open and clearer. The woofer has less of an “air spring” behind it, so it is more closely reproducing the music in the recording.

I have also spent a lot of time designing and refining crossover designs. It is a 3rd order series crossover design. A series crossover diverts the signal that is filtered out for one driver, and diverts it to the other driver. And so a series crossover can be slightly more efficient, and they tend to have a smoother more even impedance; which can make them better for use with tube amplifiers.

A transmission line speaker cabinet is a tuned “column” of air behind the driver - it has lower distortion and greater bass extension that conventional sealed or ported designs. I used a program called Hornresp (short for Horn Response), and carefully matched the computer acoustic model to the cabinet design, using DataCAD.

The total cost of the pair of woofers and a pair of the dome tweeters is about $50 - both are Dayton Audio units from Parts Express. The crossover uses all air core inductor coils, with larger gauge coils for a lower DCR. This is important for the best possible bass quality. We highly recommend bypass capacitors, that open up the soundstage with clear layered and extended treble. The benefits of high quality crossover components cannot be overstated. The build manual includes clickable links for 3 options - “good, better, best” lists of crossover parts quality.

These speakers are average sensitive - the woofer is rated at 86.8dB @2.83V @1 meter. But the crossover lowers this somewhat, and the transmission line may increase it somewhat. I listen at a lower volume setting on my preamp than the other speakers I own. The MLTL-4 speakers are 4-6 ohm nominal impedance - and has a minimum of about 4.0 ohms. I am using the amazing AkitikA GT-104 amp - it is rated at 60W/ch @ 4 ohms and ~35W/ch @ 8 ohms - it barely gets warm even after long listening sessions. Any amp that is rated for ~4 ohm speakers will probably work very well, with the MLTL-4 speakers.

The manual includes drawings in inches and in millimeters, and includes a stand that integrates with the chamfered cabinets. Also included are CNC version of the panels. I can provide the CAD files for these, if you want to build it this way.

We are very happy to announce that you are now able to order assembled crossovers for the MLTL-4! E-Zee’s Crossovers has “good/better/best” parts lists that are similar to our build manual - all air core inductor coils, metalized film capacitors, and very low/non-inductive resistors. If you want to build one of our MLTL-4 speakers - but building the crossover was holding you back - then you have this option. Visit their website, and email them for pricing. E-Zee’s Crossovers <elon@ezeescrossovers.com>

The XSim graphs shown are the MLTL-4 response and impedance that are based on the FRD and ZMA data from Dayton Audio.

The crossover shown are the “better” option listed in the build manual - air core inductor coils, metalized film capacitors with bypass caps.